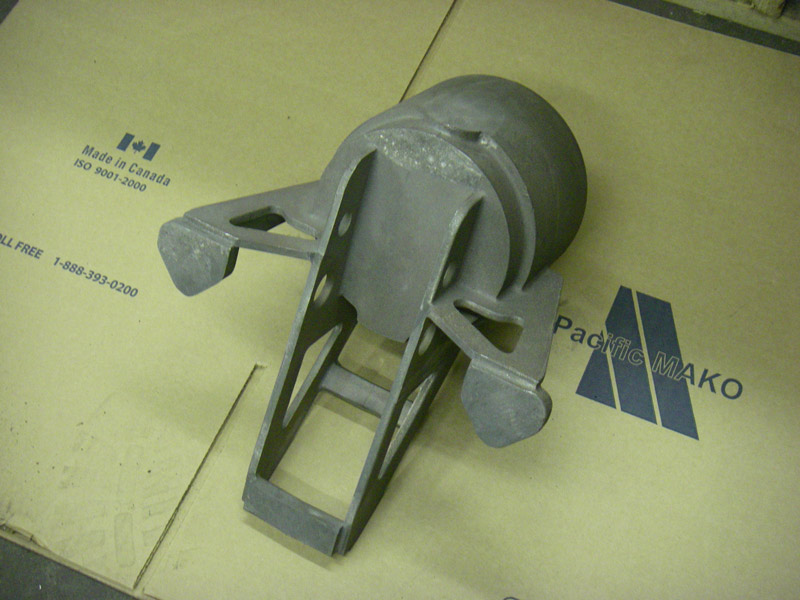

PACIFIC MAKO FOUNDRY

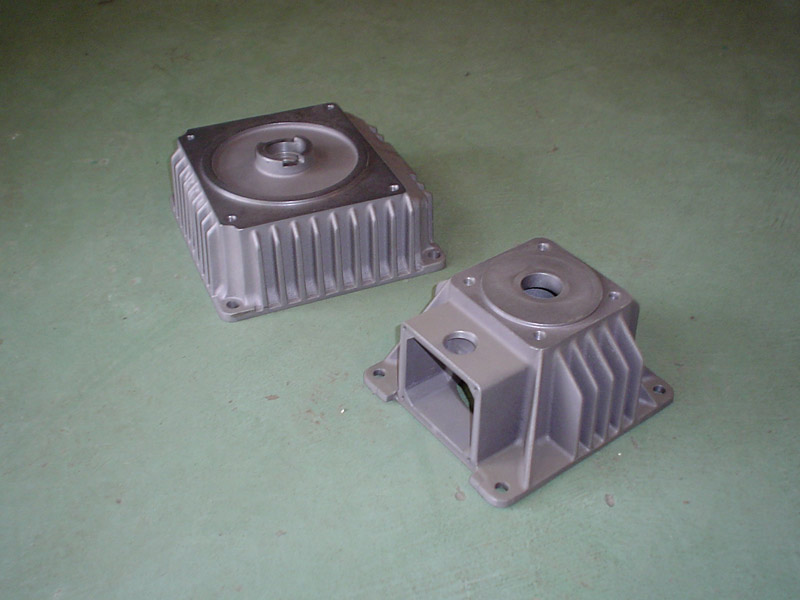

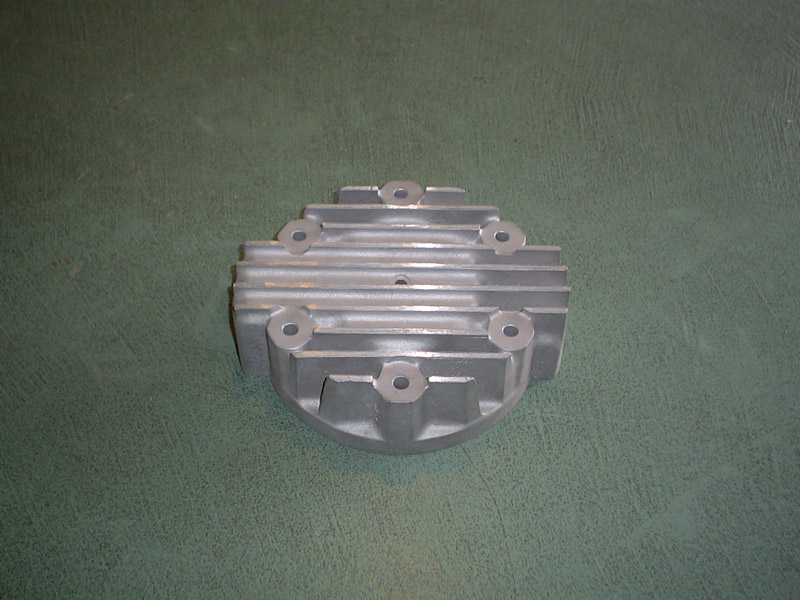

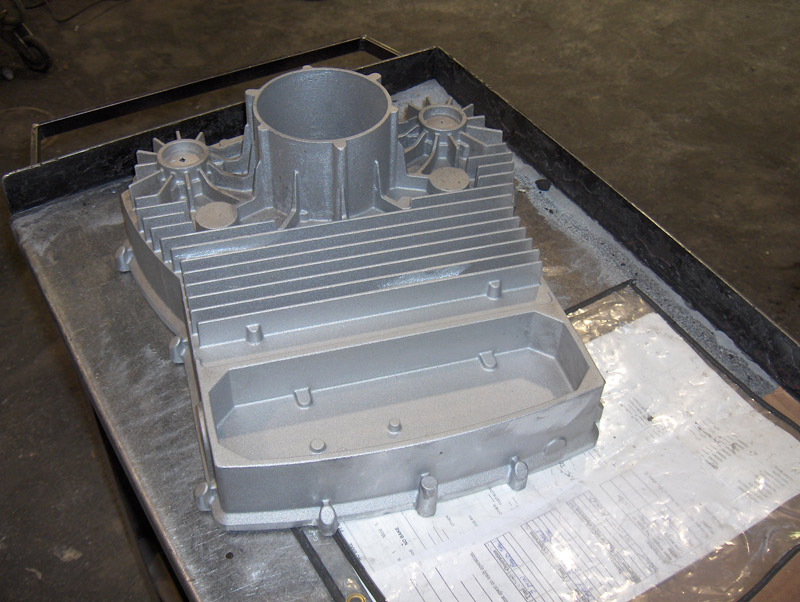

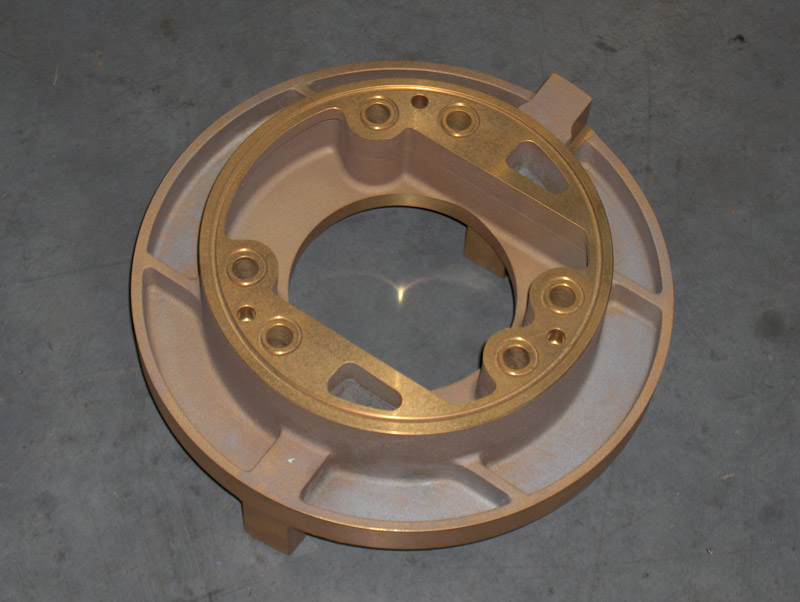

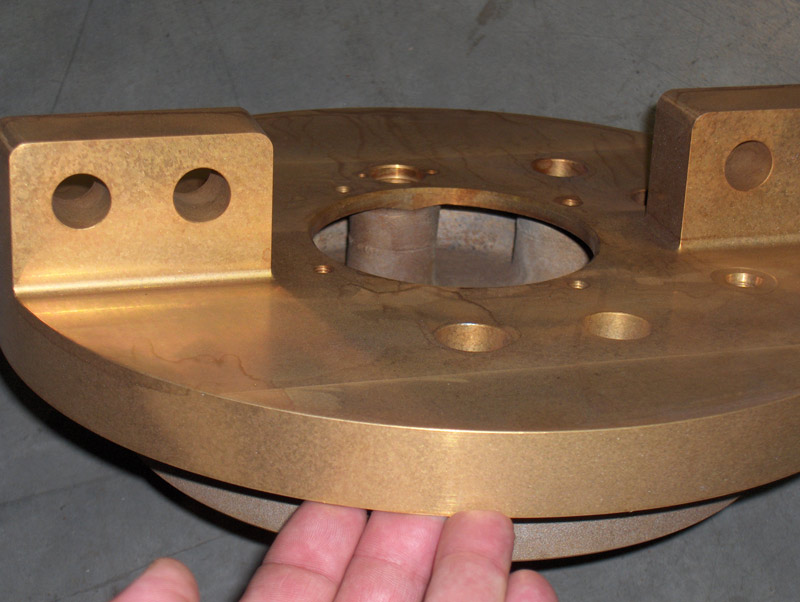

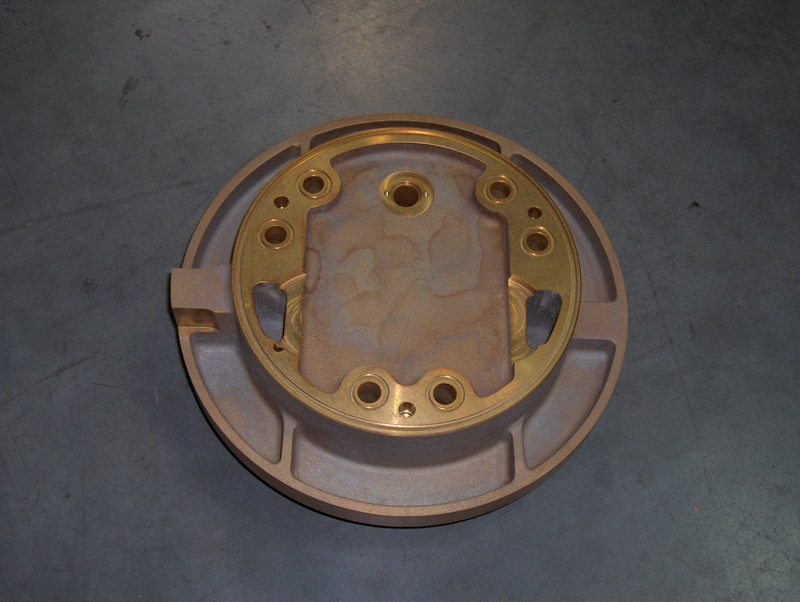

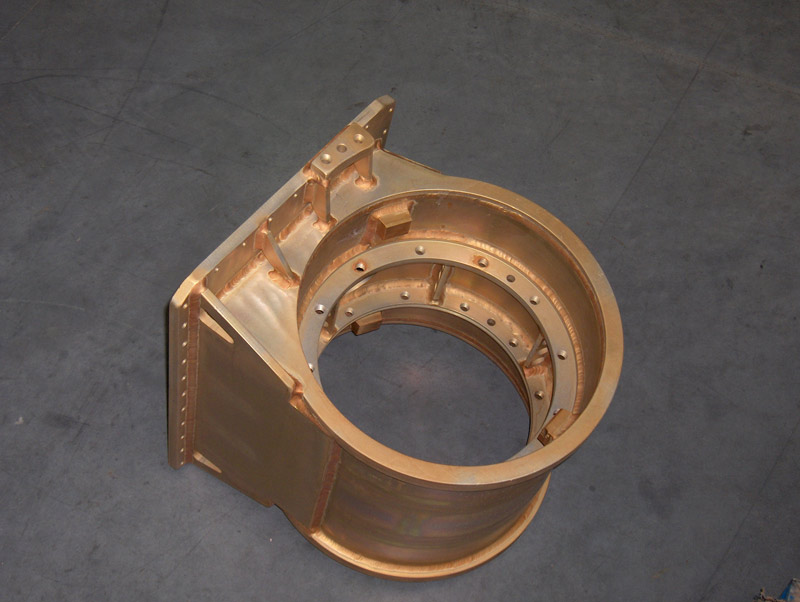

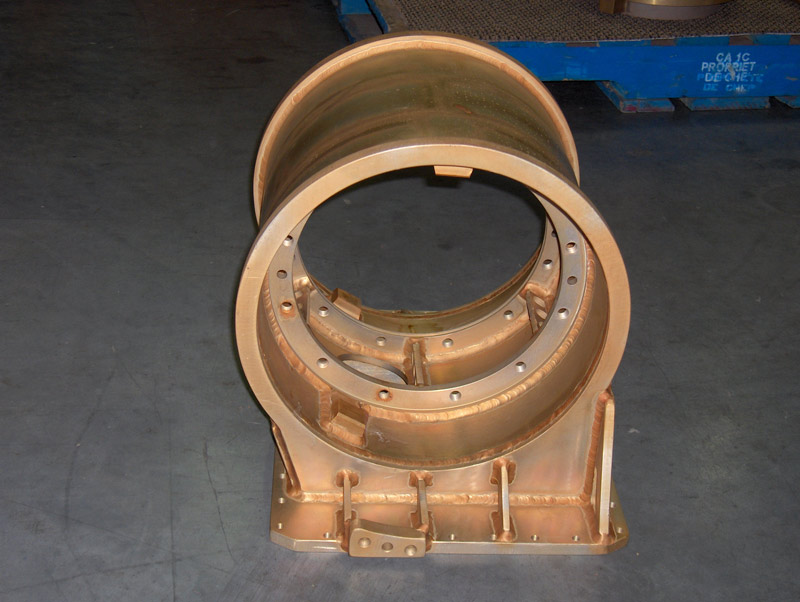

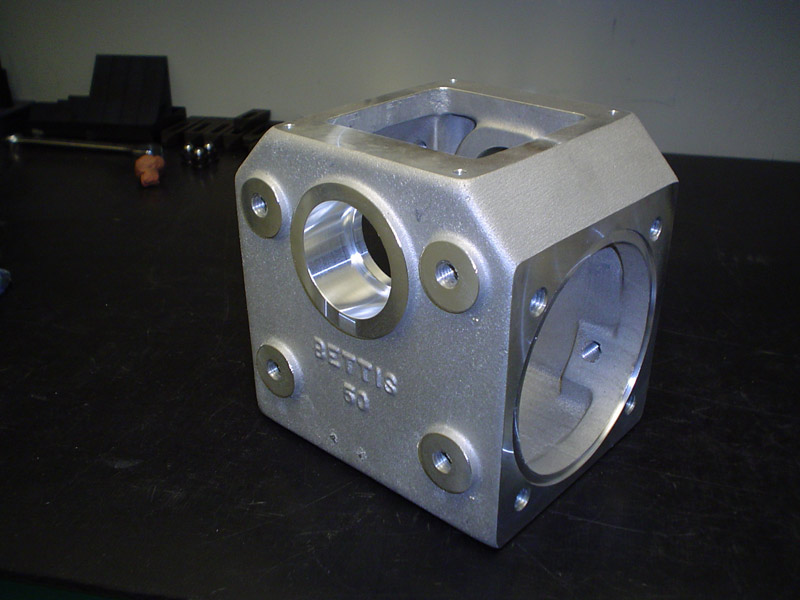

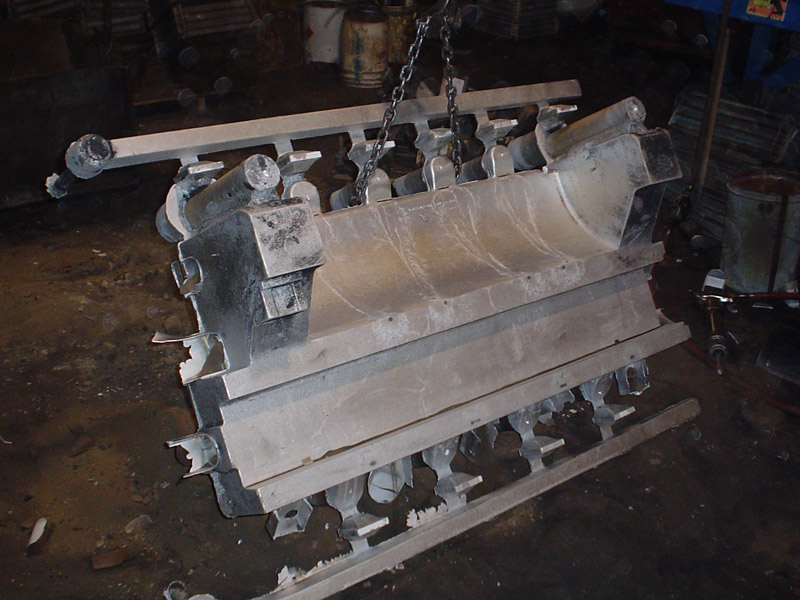

For Over 75 Years We've Provided Aluminum Casting

Solutions For A Variety Of Applications

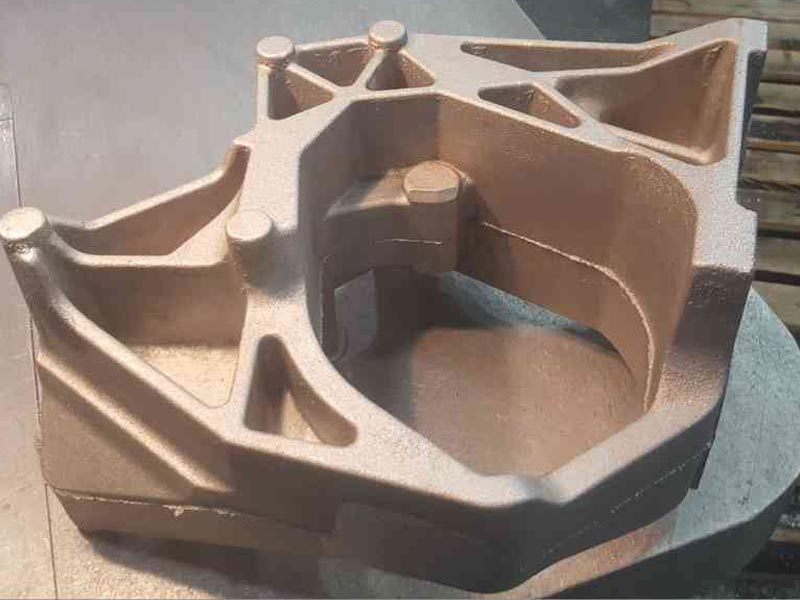

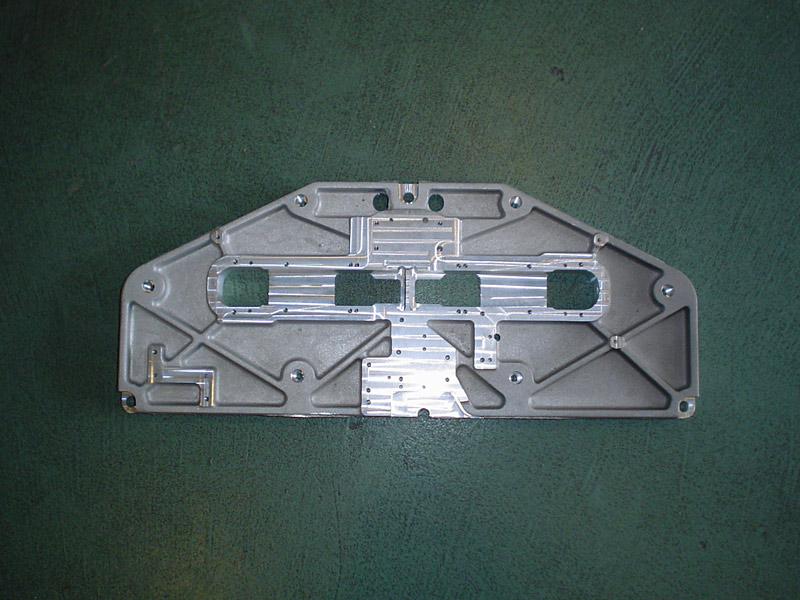

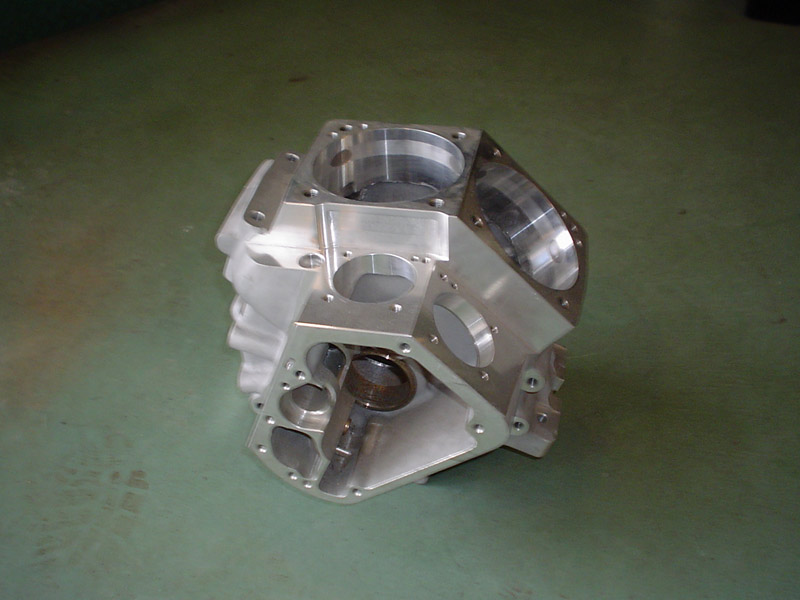

We Have Decades Of Experience In Managing The Entire Spectrum

Of Production Services For Our

Clients

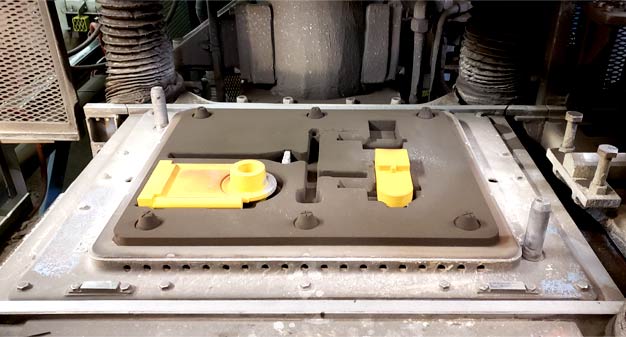

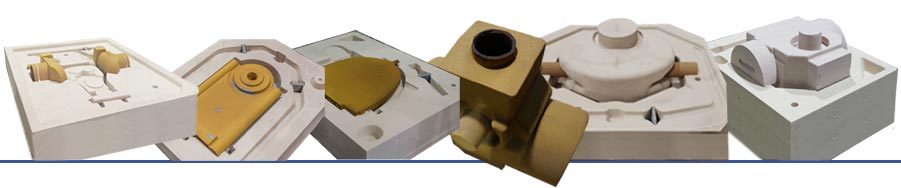

Our Facility Is Equipped To Make Consistent Molds Accurately

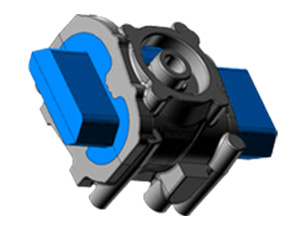

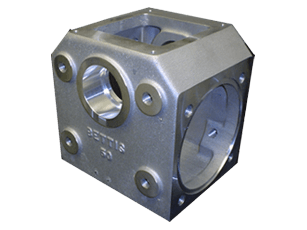

- Forestry

- Oil & Gas

- Mining

- Marine

- Transportation

- Heavy Equipment

We've Produced Aluminum Casting Components For Various Industries

OUR VALUES & PHILOSOPHY

- Our Company:

- ... is dedicated to providing solutions for all of our clients.

- ... enjoys providing design suggestions.

- ... takes on challenging and complex casting applications.

- ... is always professional and friendly.

- ... offers reliable service.

- ... is dedicated to continuous improvement.